Extrusionsprototyping und Massenproduktion

Wir bieten Folien-/Platten-Prototyping mit Hilfe von Massenproduktionsmaschinen!

Die meisten Folien- bzw. Platten-Prototyping-Maschinen können Prototypen mit einer Breite von 30 bis 300 mm verarbeiten. Die von uns angebotene Prototyping-Maschine ist hingegen in der Lage, Prototypen bis zu einer maximalen Breite von etwa 800 mm herzustellen. Die Maschine ist zudem in der Lage, bis zu drei Typen und fünf Schichten zu verarbeiten, was eine hohe Nachfrage generiert. Wir unterstützen Anfragen für hochpräzises Prototyping und Massenproduktion.

Eigenschaften

Es können einschichtige Folien bis hin zu Folien/ Platten mit drei Typen und fünf Schichten mit einer T-Die-Breite = 1.000 mm geformt werden.

Das Extrusionsprototyping von Folien/Platten ist von einer einzigen Schicht bis hin zu drei Typen mit fünf Schichten möglich. Damit können wir das Prototyping einer Vielzahl von Folien-/Plattenkonfigurationen entsprechend den Bedürfnissen unserer Kunden realisieren. Des Weiteren kann für das Prototyping eine Vielzahl an Harzen verwendet werden, darunter Allzweckkunststoffe sowie technische Superkunststoffe. Zudem stehen Inline-Folienstärkemessung, Schutzfolienlaminierung, thermische Laminierung und verschiedene Auswertungsdienste zur Verfügung.

Einschichtige Folien bis hin zu Folien/ Platten mit drei Typen und fünf Schichten

Unser Portfolio umfasst einschichtige Folien sowie Folien/Platten mit drei Typen und fünf Schichten. Wir bieten Ihnen eine breite Palette von Prototyp-Harzen, darunter Standardkunststoffe, technische Kunststoffe und supertechnische Kunststoffe. Für weitere Details stehen wir Ihnen gerne in einem persönlichen Beratungsgespräch zur Verfügung.

Dickenmessung mit Röntgenstrahlen, auch mit Prototypmaschinen

Optische Multilayer-Prototyping-Anlagen ermöglichen eine qualitativ hochwertige Prototypenfertigung mit detaillierter Dickenmessung im Prototypenstadium, die zur Massenproduktion beitragen kann.

Schutzfolien für Prototypen

Um Kratzer zu vermeiden, die bei der Handhabung nach dem Prototyping entstehen können, besteht die Möglichkeit, eine Schutzfolie aufzubringen.

Extrusionsprototyping ist auch für optische Folien/Platten möglich.

Mit der optischen Mehrschicht-Prototyping-Maschine ist die Extrusion von optischen Folien/Platten möglich. Im Gegensatz zu Allzweckmaschinen können wir mit dieser Maschine qualitativ hochwertige optische Folien/Platten liefern.

Drei-Typen-Mischmaschine verfügbar

Das Harzgranulat kann trocken gemischt werden. Zusatzstoffe, Farbstoffe usw. können ebenfalls verarbeitet werden. Flüssigkeiten und Pulver können jedoch nicht verwendet werden.

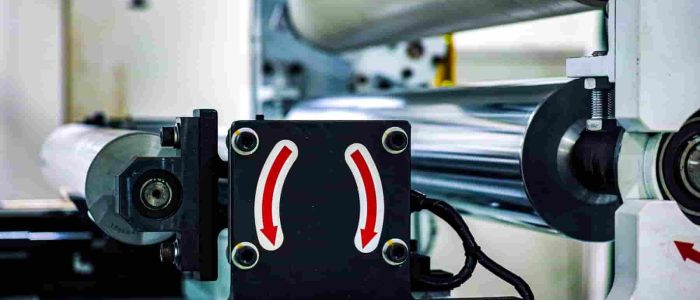

Thermisches Laminierverfahren

Unterschiedliche Materialien können im Rolle-zu-Rolle-Verfahren unter Wärmeeinwirkung miteinander verbunden werden. Substrate können mit thermoplastischen Substraten verklebt werden.

Technische Spezifikation

Optische Mehrschicht-Prototyp-Maschine

Bis zu 3 Typen und bis zu 5 Schichten / Dickenmessung / Beidseitige Schutzkaschierung / Optische Anwendungen möglich / Drei-Typen-Mischmaschine / Thermokaschierung möglich

Produktspezifikation

| Name | Optische Mehrschicht-Prototyp-Extrusionsmaschine |

| Extrusionsmaschine | Nicht belüftet L/D 36 |

| T geformtes Die (in mm) | 1.000mm |

| Schraubendurchmesser (mm) | Φ65 mm x 1, Φ40 mm x 2 |

| Extrusionstemperatur (°C) | ca. 400°C |

| Gießeinheiten | Luftkammertyp, Luftmessertyp, Gummi-/Metallspalttyp, UF-Walze/Metallspalt, Metall/Metallspalt |

| Plattenbreite, -dicke | Breite: ca. 800 mm Dicke: ca. 1.000㎛ |

| Erforderliche Rohstoffmenge (kg) | 200 kg oder mehr (auf Anfrage) |

| Weiteres | Bis zu drei Typen und fünf Schichten im Feedblock. Einsatz für optische Anwendungen möglich. Kompatibel mit supertechnischen Kunststoffen (bis zu 400°C). *Details werden individuell besprochen. Entfeuchtungstrockner, Rohmaterialmischung (Drei-Typen-Mischung aus einem Hauptmaterial + 2 Untermaterialien)/Extrusionsmaschine Dickenmessung (Röntgen in-line) Beidseitige Schutzlaminierung möglich Thermische Laminierung möglich Begutachtung vor Ort möglich |

- TOP

- Development Division

- Extrusionsprototyping und Massenproduktion